Course Overview

This 5-day course focuses on safety engineering studies through the examination of real-world case studies. Participants will delve into various safety engineering methodologies including Hazard Identification (HAZID) and Hazard and Operability (HAZOP) studies, plant layout analysis, Quantitative Risk Assessment (QRA), and consequence analysis methodologies.

Through a combination of theoretical lectures and hands-on case studies, participants will gain practical insights into safety engineering practices and enhance their ability to identify, assess, and mitigate risks in industrial settings.

Participants

Safety engineers

Process engineers

Plant managers

Prerequisites

Basic understanding of safety engineering principles

Familiarity with industrial processes and operations

Learning Assessment

Continuous assessments all-along the program.

Final assessment including a presentation in front of a jury

Program

Day 1: Introduction to Safety Engineering Studies

Overview of safety engineering methodologies

Importance of safety studies in industrial environments

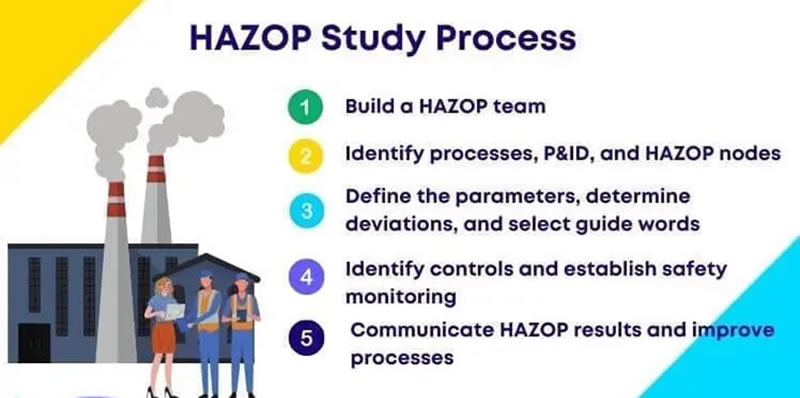

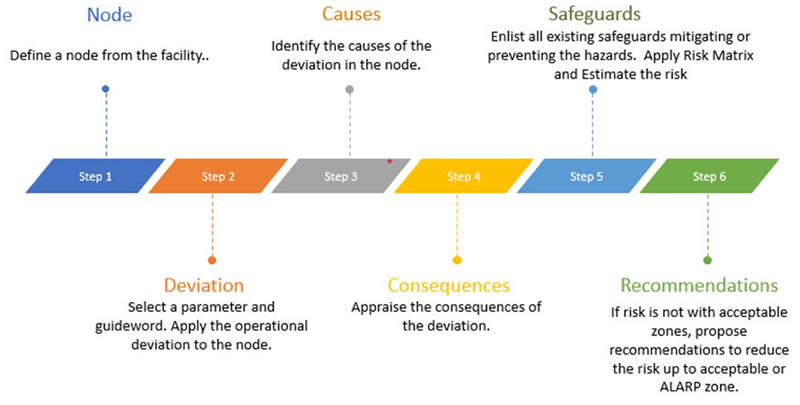

Introduction to HAZID and HAZOP workflow and application

Day 2: Hazard and Operability (HAZOP) Studies

Understanding the HAZOP process

Application of HAZOP studies in identifying process hazards and operability issues

Hands-on exercises and case studies

Day 3: Plant Layout Analysis

Importance of plant layout in process safety

Principles of effective plant layout design

Case study analysis of plant layout considerations

Day 4: Quantitative Risk Assessment (QRA)

Introduction to Quantitative Risk Assessment (QRA)

Methodologies for conducting QRA

Application of QRA in assessing and managing risks

Day 5: Consequence Analysis Methodologies

Overview of consequence analysis methodologies

Techniques for assessing the consequences of process safety incidents

Case studies and practical applications